Mahjong Manufacturing

- The Malada Mahjong manufacturing facility is equipped with state-of-the-art machinery and overseen by skilled technicians. This allows us to produce high-quality Mahjong products efficiently and at competitive prices.

- Home

- Production Process

How Mahjong Are Made

We are a well-known factory of Mahjong located in Shenzhen, China, relying on our modernized factory and experienced professional team, our Mahjong mainly serves a variety of entertainment and gaming industries for a wide range of entertainment occasions. The production of our mahjong consists of several steps, including: raw material ordering, cutting, polishing, marking, coloring, cleaning, quality inspection, shipping, etc.. We strictly control every aspect of mahjong production to ensure that each mahjong tile meets the highest standards.

How to Make Mahjong Step by Step

#1 Raw Materials For Mahjong

We understand that the quality of the material directly affects the feel, appearance and longevity of the mahjong, so we take extra care in our selection process. The materials we use come from virgin PMMA, which has excellent quality and durability, ensuring that each mahjong tile will maintain its stable performance and appearance over a long period of time. The surface and interior of each mahjong tile is meticulously inspected to ensure that there are no impurities, air bubbles, or water stains to ensure the purity of the material and the overall aesthetics.

#2 Material Cutting

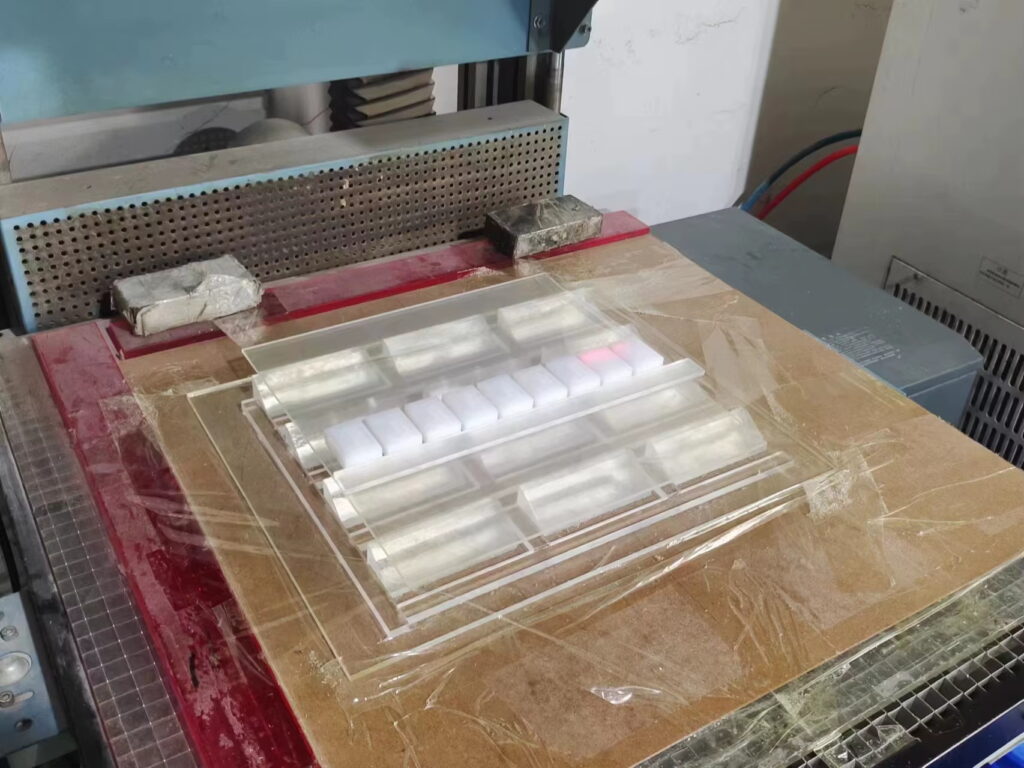

Our team of engineers will combine your size requirements and design specifications with meticulous size tuning and design adjustments during the cutting process to ensure that each piece of mahjong is highly compatible with your expectations in terms of shape, edges and details.

In order to meet the demands of mass production, we are equipped with four state-of-the-art cutting machines, each of which has been carefully tuned for efficient and high-precision cutting. This enables us to easily cope with different quantities and delivery schedules while ensuring quality. Whether it is a single small batch customization or a large-scale production, we are able to complete it efficiently and deliver it on time, ensuring that every customer receives the products that meet their requirements on time.

#3 Mahjong Polishing

Mahjong polishing is a very critical part of the mahjong making process. By using machines to grind and polish mahjong several times to remove the roughness and imperfections on the surface of raw materials, the durability of mahjong can be significantly enhanced. A finely polished mahjong tile has a smooth and tough surface that resists the wear and tear of daily use and lasts for a longer period of time. In addition, the polishing process also helps to enhance the feel and touch of the mahjong, making it a comfortable experience for the player every time the mahjong is dealt and shuffled, fully meeting the standard of high quality mahjong. We always insist on combining exquisite polishing technology with superior craftsmanship to ensure that every mahjong set meets your high demand for quality.

#4 Mahjong Making

In order to pursue higher precision and more perfect visual effects, we have introduced advanced engraving equipment imported from Germany. These equipments are equipped with extremely high precision and fast response capability, which can accurately engrave complex and detailed patterns on the surface of each mahjong tile in a very short time. Whether it is a traditional classic pattern or a customized unique design, it can be accurately rendered on each piece of mahjong with smoother lines and more details of the pattern. Compared to traditional hand engraving and early engraving machines, this equipment is not only able to carve out finer details, but the symmetry and consistency of the patterns have been significantly improved, ensuring that each mahjong tile looks extremely beautiful.

#5 Coloring

During the color filling process, engineers precisely control the optimal distance between the tool head and the mahjong tile to ensure that the ink is evenly spread across the surface so that the colors do not bleed into each other, and to ensure that there is not too much or too little ink applied.

In addition to controlling color bleed, engineers need to make sure the ink is just the right amount of dryness. Inks that are too dry to smudge easily will result in uneven colors, while inks that are too thin are prone to air bubbles, so we strictly control this step to ensure that the overall colors are vibrant and natural.

Lets Connected

Lets Get In Touch With Our Team

Head Quarter Office

Lumbung Hidup St. 425 East Java Block ABC

Hello@Email.com

(+86)159 9482 0723

Monday - Friday

08.30 AM - 6 PM

Do You Need Unique Mahjong For Your Brand? Contact Us Now

Malada Make Your Idear Come Ture